Tesla cancels Gigacasting process : Sources

Tesla cancels Gigacasting process : Sources Gigacasting streamlines car part production by eliminating large, single-piece casting, cutting assembly steps, increasing durability and reducing costs.

Tesla cancels Gigacasting process : Sources Tesla has reportedly withdrawn its ambitious Gigacasting plan, a pioneering manufacturing process. The move reflects the company’s retrenchment amid declining sales and increasing competition in the electric vehicle market, two sources said.

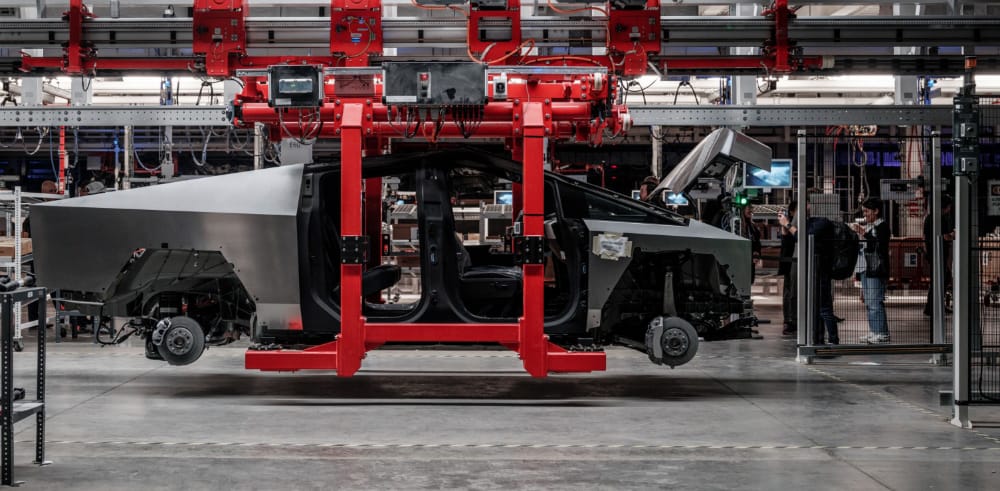

Tesla cancels Gigacasting process : Sources Tesla pioneered Gigacasting, an innovative method that uses massive presses with extreme clamping pressure to die-cast large sections of a car’s underside. Traditionally, a vehicle’s underbody consists of many different parts, but Gigacasting streamlines the process by consolidating them into fewer, larger components.

Last year, Tesla began developing a new small-vehicle platform with the intention of producing the underbody in a single piece, according to an exclusive Reuters report in September. The effort, informed by insights from five sources familiar with Tesla’s gigacasting operations, aims to revolutionize manufacturing by significantly streamlining processes and reducing expenses in the long run.

Tesla cancels Gigacasting process : Sources However, Tesla has recently decided to discontinue this initiative, instead choosing to follow its established practice of casting vehicle underbodies in three sections. These sections include two GigaCast sections for the front and rear, as well as a middle section crafted from an aluminum and steel frame to house batteries. The decision, according to two sources familiar with the matter, mirrors the approach taken by the company for its two previous models: the Model Y crossover SUV and the Cybertruck pickup.

Tesla’s move away from single-piece gigacasting has remained unknown until now, as the automaker declined to comment upon request.

This strategic move to postpone a potential manufacturing breakthrough reflects Tesla’s broader strategy of reducing short-term spending. The adjustment comes amid declining sales and profit margins, softening global electric vehicle (EV) demand and increasing competition from rivals such as China’s BYD.

To deal with these challenges, Tesla recently cut its global workforce by more than 10%. Additionally, the company saw the departure of several senior executives, either voluntarily or involuntarily.

Tesla cancels Gigacasting process : Sources the Gigacasting initiative underscores Tesla’s pragmatic approach to understanding the emerging landscape of the EV market. By prioritizing cost efficiency and streamlining operations, Tesla aims to maintain its competitive edge in an increasingly crowded market.

These actions signal a notable strategic pivot for Tesla, prioritizing the advancement of self-driving technology over aggressive expansion of electric vehicle (EV) sales volume – a shift that has surprised many investors.

Tesla cancels Gigacasting process : Sources made ahead of Tesla’s announcement in late February to halt development of the highly anticipated Model 2, which would have been the first more affordable vehicle to use single-piece GigaCasting. Reuters initially reported the Model 2’s cancellation on April 5.

This strategic restructuring outlines the company’s strategic response to Tesla’s evolving priorities and market dynamics. By refocusing efforts on self-driving technology, Tesla aims to solidify its position as a leader in autonomous driving technology, which it believes will shape the future of transportation.

While these decisions may come as a surprise to some stakeholders, Tesla is committed to innovation and strategic adaptation in pursuit of its long-term vision for sustainable transportation.

During its April 23 earnings release, Tesla revealed a revised strategy to deliver “more affordable” vehicles after canceling the anticipated Model 2, initially priced at $25,000 and arriving in the second half of 2025. The launch was planned, which contributed to earnings that beat Wall Street estimates.

Tesla executives outlined a streamlined approach, opting to leverage existing platforms and production lines to introduce a budget-friendly model. Although Chief Executive Elon Musk avoided giving specifics about these upcoming offerings or their pricing targets during the investor call, the company signaled a commitment to delivering accessible electric vehicles through an accelerated production process.

This pivot reflects Tesla’s ongoing efforts to adapt to market dynamics and balance innovation with operational efficiency. By reusing existing resources and infrastructure, Tesla aims to accelerate the rollout of affordable models, addressing both consumer demand for accessible electric vehicles and the company’s strategic objectives for sustainable transportation.

Tesla hasn’t completely scrapped its small vehicle platform for the Model 2. Instead, it is moving toward building a self-driving robotaxi based on the same platform, according to an April 5 report by Reuters. According to one of the sources familiar with the matter, suppliers associated with Tesla’s gigacasting operations are now adjusting the three-piece process for the next-generation vehicle.

Both insiders revealed that the carmaker had decided to stop using the more complex one-piece casting process last time. According to sources, the decision was driven by the need to accelerate development of the Model 2, which has since been canceled, and prevent potentially costly setbacks or production issues.

Major advance investment

Tesla and Musk promote gigacasting for its long-term cost reduction benefits. However, experts note its demanding nature and heavy initial investment.

Vehicle manufacturing experts highlight Tesla’s cautious approach toward gigacasting, citing past struggles with complex vehicle launches. For example, the Cybertruck faced significant delays and pricing discrepancies upon release.

Terry Woychowski, president of Caresoft Global, explains that delaying one-piece gigacasting allows Tesla to avoid significant short-term capital commitments. While ideal, such a method would be costly to implement.

James Womack, a former research director at MIT, sees Tesla’s pivot as a response to pressures in the competitive EV market. They suggest that, while innovative, gigacasting may not pique consumer interest.

In short, Tesla’s decision reflects a balance between innovation and practicality, while prioritizing efficiency and financial prudence amid industry challenges.